He has worked as an accountant and consultant for more than 25 years and has built financial models for all types of industries. He has been the CFO or controller of both small and medium sized companies and has run small businesses of his own. He has been a manager and an auditor with Deloitte, a big 4 accountancy firm, and holds a degree from Loughborough University. The work in process at the end of the accounting period is calculated as 35,000.

How to calculate energy

- It’s a good idea to calculate your WIP inventory on a regular basis, such as weekly or monthly.

- These costs include direct material, labor, and manufacturing overhead costs.

- If you’re wondering how to calculate WIP inventory, follow these steps.

- Work in process (WIP) is inventory being worked on but isn’t ready to be shipped out yet.

- Calculating the value of WIP inventory involves associating a cost with a percentage of completion.

The products that have not been finished are labeled as work in process. Accountants must use specific procedures to place values on these products for your company’s financial statements. For ecommerce businesses, it provides a way to account for the investments in materials and labor that have not yet resulted in finished goods ready for sale. Proper WIP ecommerce inventory management is crucial for optimizing production workflows, controlling costs, and improving overall operational efficiency. WIP tracks how manufacturing costs flow through the production process, capturing costs for goods that aren’t finished.. Production costs include raw materials, labor used in making goods, and allocated overhead.

Important Metrics in the WIP Inventory

For further assistance on product payroll and supply chain manufacturing, contact Qodenext today. Tracking the status of in-process goods and work orders is crucial to ensure efficient production processes and optimal stock levels. Doing this with spreadsheets or pen-and-paper is possible for very small or simple operations. However, a much more comprehensive solution for companies of any size lies in manufacturing software. Work in process inventory is a key component of your production process and overall inventory management.

- Training staff involved in inventory tracking can help minimize errors.

- We’re looking at how to calculate work in process inventory and walking through the benefits of using this powerful, informative component of managing your inventory.

- Another best practice is to regularly review and update your WIP inventory levels.

- Every business that produces goods goes through different stages before the final product is ready.

- You will need financial statements and records of expenses related to production during the accounting period.

What’s a 3PL? Simplifying Logistics for Businesses

Once the manufacturer gets the raw materials in-house, the process for making the finished products begins. The inventory in the process of turning into finished products from raw materials is called work in process inventory. One way to reduce your WIP inventory levels is to streamline your production process.

Manage your inventory and bookkeeping easier

6) Right size packagingUse a posted mailer and box matrix by product family to control DIM and damage. 5) Print labels lastCreate shipping labels after the final scan at pack. This prevents reprints and removes half finished orders from the line. Ask a warehouse operator, and it’s the mountain of boxes that “just need labels.” Both are right, but only one trips over it on the way to lunch.

- It measures the speed of work-in-process through a plant by quantifying the value of shipments in terms of the value of WIP.

- For example, wood used in furniture making or metal used in the production of car parts are considered direct materials.

- Figuring out WIP inventory is an involved process because it involves associating a cost with a percentage of completion.

- Work in process (WIP), sometimes called work in progress, is a type of inventory that lies in the manufacturing pipeline between the raw materials and finished goods inventories.

- In a typical manufacturing setting, products move through various stages, such as raw materials, work-in-process, and finished goods.

Eliminate production bottlenecks

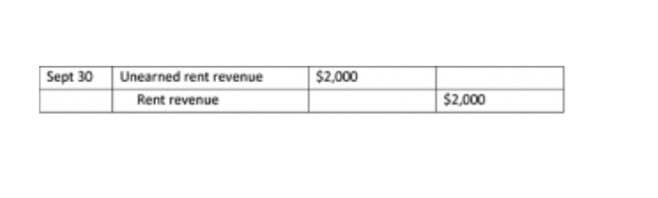

The terms ‘work in process’ and ‘work in progress’ are frequently used interchangeably, yet they can mean different things depending on the business. This efficiency enabled the company to quickly introduce modern technologies. Double Entry Bookkeeping is here to provide you with free online information to help you learn and understand bookkeeping and introductory accounting. WIP inventory directly affects Cost of Goods Sold (COGS) and overall profitability.

Grow Your Business With TranZact.

- Otherwise, the raw materials and the usage of these raw materials count as “losses” for your business.

- For example, if your WIP inventory shows that you have enough materials to complete a batch of products, but your raw materials inventory says otherwise, you could run into issues.

- In accounting or financial reporting, ‘work in process’ refers to the value of partially completed goods or products within the production process.

- Identifying and applying appropriate WIP management techniques is pivotal for organizations seeking to create processes for improved efficiency and financial clearance.

- Finally, one of the biggest challenges in managing WIP inventory is integrating it with your overall inventory management system.

- A piece of inventory becomes labeled as work-in-progress when raw material combines with labor.

The value of your business’s inventory is constantly changing as products are received, assembled, stored, and sold. Inventory accounting is an important aspect of your fulfillment process because the cost of buying and storing a product is a major factor in your asset calculations for your business. The beginning WIP inventory is a type of carryover from the last accounting period‘s balance sheet. The current cycle’s beginning WIP inventory cost should be the exact same as the last cycle’s ending WIP inventory cost. Any inventory that moves from raw materials and is manipulated by human or machine labor, but is not yet a complete product, is considered to be work-in-process inventory.

Collaborate with production and accounting teams to ensure all figures align. Flowspace is the best way to optimize your work in process inventory levels and support successful partnerships work in progress inventory with manufacturers. As with most inventory management KPIs, ensuring an efficient inventory management process is critical to optimizing the work in process inventory. One of the best ways to do that is to work with a third-party logistics partner to manage inventory.

Inventory analytics and reporting: Turning data into impacts

This article will provide a comprehensive guide to understanding WIP inventory levels. We’ll break down the concept, explore its importance in ecommerce operations, and explain how to calculate work in process inventory for your own production process. However, at the same time, WIP also flags potential issues in your production process, such as bottlenecks or delays. If unresolved, these issues could lead to higher holding costs or possible cash flow problems down the line.

Multi-warehouse operations face many inventory management challenges, especially when managing storage and order fulfillment for multichannel sales environments. Outdated and siloed technology does not provide the integrated, real-time data necessary to provide the… Customer satisfaction is also a benefit of using work in process inventory. With this, customers will get their products on time because there will be a proper flow in the manufacturing. You will be able to deliver the items on time and also ensure everything is of high quality.